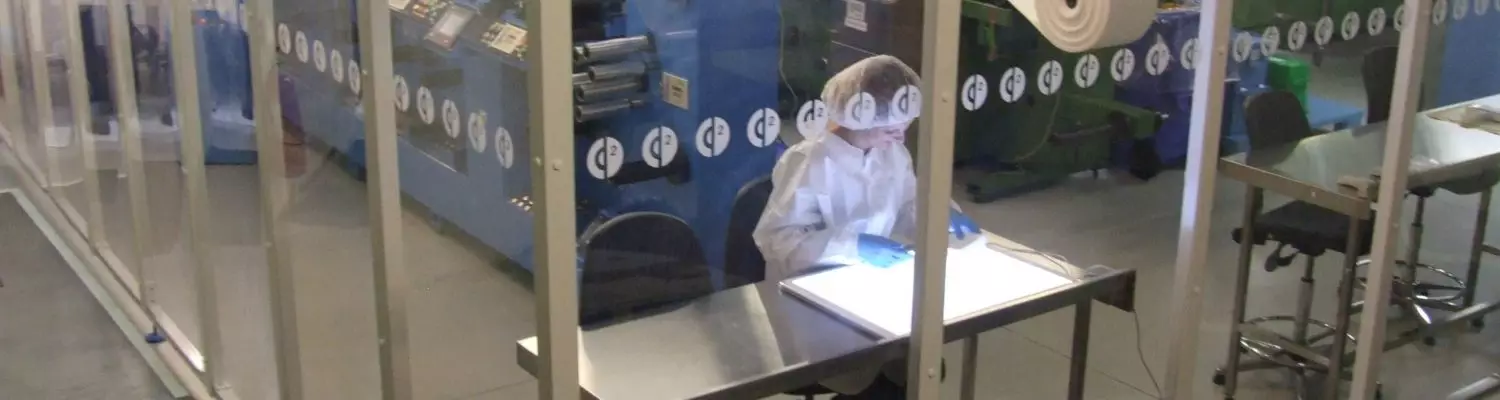

ISO 13485 cleanroom

Quality is a priority in everything we do at BDK. We manufacture medical devices and medical device components to ISO 13485:2016 standard, and a cleanroom is a prerequisite. Our cleanroom is designed to control the level of airborne particles that are present during the production process and altogether, our ISO 13485 cleanroom helps us to provide an efficient, controlled manufacturing process.

ISO 13485:2016 is vital for medical manufacture. BDK’s commitment to quality ensures that your product is manufactured to your specification, as well as with patient care in mind.

Bioburden Testing and Control

A controlled environment is fundamental for manufacture of medical devices and components. Strict hygiene requirements are employed because it is vital that every device is within acceptable bio-burden limits. By producing these medical device components within a controlled, and controllable environment the quality, safety and effectiveness of medical devices can be ensured.

Bioburden testing also known as microbial limit testing, is used to ensure our cleanroom is safe for medical device manufacturing. Bioburden describes the number of microbial bacteria living on a surface or item, such as a device or component, before the final sterilisation process. This is an essential procedure in our quality control system and allows us to monitor microbial levels.

Cleanrooms are categorised into different classes relating to their filtration level; this is calculated by the number of particles per cubic meter at a specific particle size. At BDK, we utilise a Class 7 cleanroom, also known as ISO 7 and Class 10000 cleanroom. All of the air passes through a High Efficiency Particulate Air (HEPA) filter before it is delivered to the cleanroom in order to trap particles that are larger than 0.3μm. As well as this, extensive training is provided to employees to ensure that the strict hygiene requirements are met.

Bioburden testing and control is a vital element of producing medically approved materials. If you need reliable and innovative healthcare solutions, contact us today to discuss your requirements.

If you are looking for a medical device manufacturer with a reputation for high quality project management and thorough bioburden testing, look no further. BDK can be the cleanroom manufacturer and project manager with control of sterilisation for you.